Description

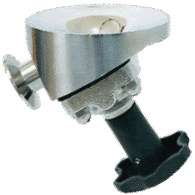

Bio-Flo® II valve bodies are manufactured from the same forged 316L material as the standard Bio-Pro® forged bodies. All Bio-Flo® II valve sizes are machined from a common raw forging with controlled chemistry per ASME BPE 2007. Bodies are available with clamp or buttweld ends and surface finishes through 10RA. Bio-Flo® II manual 304 stainless steel bonnets are provided with adjustable PPS handwheel, sanitary internals, and Viton® o-ring seal. Bonnets are autoclavable and can withstand elevated temperatures to 300° F.

Here are some key standard features to consider for your next requirement:

- Low ferrite DIN 1.4435 316L forged body sizes 1/4″-4″ with controlled sulfur content to ASME BPE 2007 0.005-0.017 with 3.1B Material Certification

- Autoclaveable Viton® o-ring sealed 304SS stainless steel manual bonnet with adjustable PPS thermoplastic handwheel

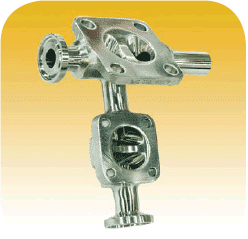

- Thermoplastic piston type pneumatic actuators with your choice of popular controls for feedback (Westlock, StoneL, Burkert, etc.)

- FDA and USP Class VI (Sections 87 & 88) conforming steam grade EPDM, TFM/EPDM, and TFM/Viton® backed diaphragms

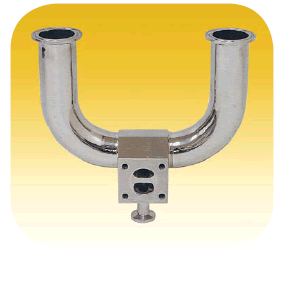

- Specialty fabricated sterile access and GMP style valves

- Zero DL machined block body style valve types – Point of Use, T-pattern, Divert style, Tank Bottom, and many others specialties as designed

- Interchangeable diaphragms and topworks with most other manufacturers

- Extensive on the shelf inventory for project support