Description

Product Defined / What it does:

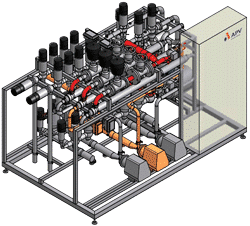

When you cannot CIP an area or the equipment cannot be easily disassembled for clean-out-of-place cleaning, Sani-Matic’s Boosted Pressure Systems are designed to provide the appropriate amount of pressure to chemical drop stations located throughout your plant for operators to perform thorough cleaning of hard-to-clean areas. Both Impact RFS and Central High-Pressure Systems are available.

Applications:

Can be used to clean these applications: Fillers, Mixers, Blenders, Conveyors, Totes, Walls, Equipment Exteriors, Floors, Spiral and I-Line Freezers, Platforms

Top Benefits of the Boosted Pressure Systems:

- Faster than manual cleaning

- Boosted pressure systems removes soil efficiently, while minimizing cross-contamination

- Technology controls chemical and air injection to create clinging foam that ensures adequate dwell time

- Nozzles use fewer gallons per minute at boosted pressure than other typical hose guns

- Industry Standard Compliance: UL 508A, ANSI/ISA-88 Batch Control, authorized to provide Canadian Registration Numbers (CRN), and helps meet FSMA and HACCP Sanitation Preventive Controls