Description

Click for brochure Click for manual

Ball Valves are used in a wide variety of high pressure applications. Two factors make them popular. First, a full unrestricted flow that allows no product restrictions through the valve. Second, the three piece design and the removal of a minimal number of bolts allows service to be performed without removing the complete valve from the line.

VNE offers two way ball valves made of T316 (CF8M) stainless steel. PTFE seats are easily removed. Clamp and Weld ends are standard. Other connections are available upon request. 1/2? through 4? sizes are available. Ball Valves meet FDA and 3A requirements.

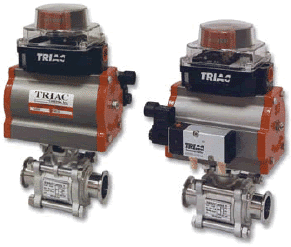

VNE offers many options on automated ball valves.

Ball Valve Specifications…. |

Important Features…. |

||||||||||||||||||||||||

|

Size:

|

1/2?, 3/4?, 1?, 1 1/2?, 2?, 2 1/2?, 3?, 4? |

|

|||||||||||||||||||||||

|

Materials:

|

Passivated 316 Stainless Steel (ASTM A351, CF8M) | ||||||||||||||||||||||||

|

Connections:

|

Clamp & Weld – other connections available upon request | ||||||||||||||||||||||||

|

Working Pressure:

|

|

||||||||||||||||||||||||

|

Temperature Rating:

|

-65 to 320 Degrees F | ||||||||||||||||||||||||

Ordering Specifications… |

|

| Specify: | • Quantity • Product description or Part No. • Size • Material Type |