Description

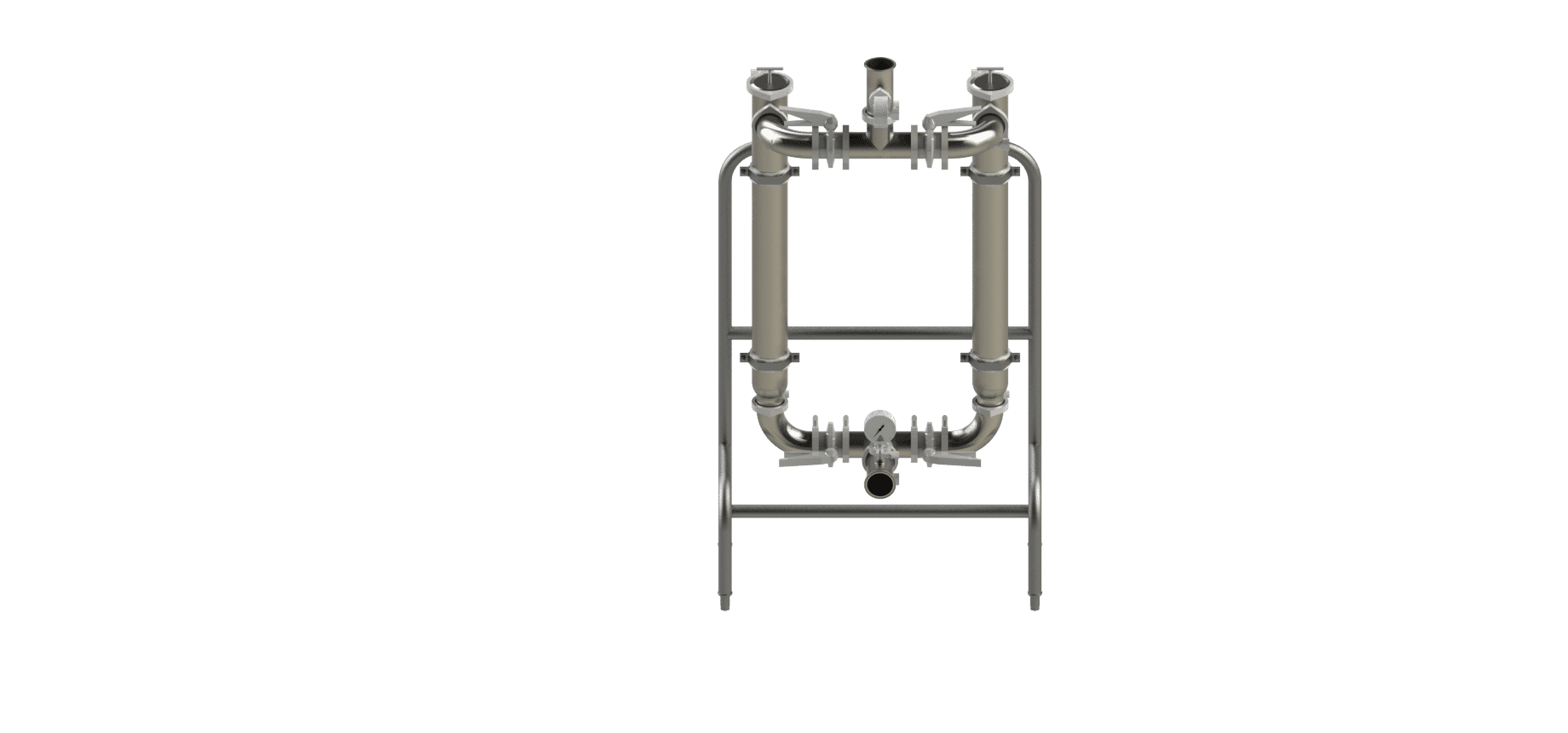

Angle-Line Strainers (Standard & High Capacity)

Product Defined:

Angle-Line Strainers allow operators to clean the strainer element without removing the strainer body from the process line, which significantly increases production uptime. They also allow for both standard (end-inlet) or reverse (side-inlet) process flow simply by changing the strainer element frame. Every sanitary process, whether it is a food, beverage, pharmaceutical, or personal care process, requires particulate straining to protect product integrity and processing equipment. With Angle-Line Strainers, you can do that while also increasing productivity.

Product Application:

Installed into processing lines to remove debris or particulates to protect product integrity and downstream processing equipment

Top Product Benefits:

- Sanitary, Standard angle-line strainers are 3-A certified when using a perforated element

- Canadian Registration Numbers (CRN), The angle-line 4” body size has CRN

- Flexible, Allows for both standard (end-inlet) and reverse (side-inlet) flow

- Convenient, Operators can clean the element without removing the strainer body from the process line

- High-Capacity Strainer, 6” body size offered, Strains particulate from higher volume processes

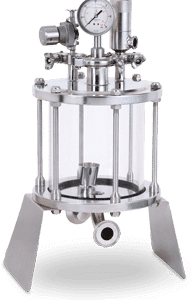

- Sight Glass & Sample Port configuration options available

**All Sani-Matic strainer products can be designed to Configured Design Offerings, just reference our Product Model Number Keys within our Components Catalog

Relevant Sani-Matic Blog Posts:

Sanitary Process Components: Taking the Strain Out of Selecting Strainers