Description

Features and Benefits

Totally

Reusable |

- Made of grade 316L stainless steel with an average interior surface finish of 20Ra or better

- Can be dismounted and reattached to a new length of hose by a factory-authorized fabricating distributor

- Significant savings compared to the cost of a completely new assembly (up to 90%)

- Available in a wide variety of sizes and end styles

- Smaller sizes (up to 1″) can be field fabricated

- Light weight

|

| Sanitary |

- Meets the stringent requirements of dairy applications

- Full flow compression seal and smooth bore design prevent bacteria build-up

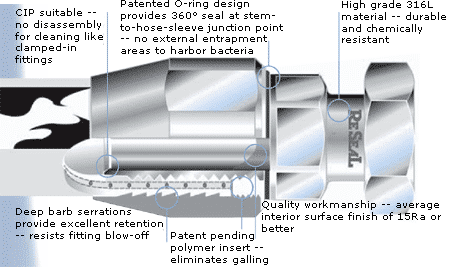

- Patented O-ring design provides 360° seal at stem-to-hose-sleeve junction point

- No external entrapment area to harbor bacteria

|

| Cleanable |

- Suitable for Clean-In-Place (CIP) procedures

- No disassembly for cleaning like clamped-in fittings

|

| Safe |

- Superior coupling retention

- No straps or bands to injure workers

|

| Inspectable |

- Quick disassembly makes inspections easy

|

Fitting Details

- ReSeal® fittings for MilkFlex® hose are available in three sizes– 51mm, 63mm, 76mm and three standard end styles

- Stems are manufactured from grade 316L stainless steel with an average interior surface finish of 15Ra or better

- Hose sleeves are available in either stainless steel or high impact polymer

|

End Connector Styles

Note: Other end styles are also available with additional welding charges.

Hose Sleeves (Polymer and Stainless Steel)

Polymer

- Light weight

- Mild chemical resistance

- Inexpensive

- Superior impact resistance

- Abrasion resistant

- CIP chemically suitable

- Non-reusable

|

Stainless Steel

- Elevated temperature

- CIP suitable

- Excellent durability

- Higher pressure ratings

- Chemically resistant

- Reusable

|

|