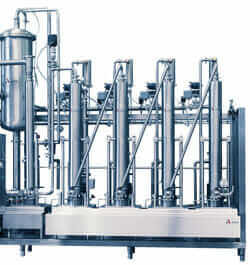

Description

FUNCTION

- Ste-Vac Heaters have been in use for decades in the dairy industry for heating milk and milk based products to high temperatures for sustained periods of time. More recently, their use has been expanded to include both heating and cooling of a broad range of fluid products.

FEATURES

- Fully insulated, stainless steel jacket reduces heat losses and provides operator safety.

- All product surfaces are available in either type 304 or type 316 stainless steel.

- Product tubing available in both 1″ and 1-1/2″ sizes and can be arranged in either series or parallel flow configurations.

- Steam heating units are furnished complete with mounted condensate removal pump. Air operated or self-acting control packages are available.

- Cooling units are internally baffled to maximize heat transfer efficiency.

- Standard heaters are supplied with a turbine-type vacuum pump for removal of condensate and non-condensable gases.

- Product returns are smooth 180º bends secured with heavy-duty tri-clamp unions. Sanitary stainless steel manifolds are furnished with parallel flow configurations.

BENEFITS

- Able to process broad range of products, from those having water-like to paste-like viscosity, including those containing undissolved solids and particulate matter.

- Units provide a broad range of processing capacities and temperature progressions.

- Unique “cool/dry tube” design and high velocity product flow enables many hours of continuous, no burn-on, performance in heating applications.

- Unit is sanitary and easily cleaned-in-place. Minimal gasketing requirement.

- Tri-clamp unions are designed to provide high product pressure capability and ready access for inspection of all product surfaces.

TYPICAL APPLICATIONS

- Pre-heating milk and other dairy products in drying and condensing operations requiring high temperatures and sustained hours of operation.

- Heating or cooling a wide range of pumpable products containing particulate matter, not possible in plate & frame and other type heat exchangers.

- Use in any fluid heat exchange application where low maintenance, trouble-free service is essential.